Insulating Glass

Insulating glass units are the most commonly used product to increase the thermal performance of a window.

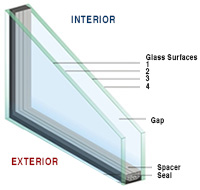

By sealing a dry air space between two or more lites of glass, insulating glass increases the thermal performance of a window. The sealed air space creates a buffer that effectively decreases energy transfer and reduces the formation of condensation.

At ITI Glass, insulating glass units (IGUs) are processed by a vertical BYSTRONIC automated line that can produce oversized units. The automated line includes a dedicated washer that has superior handling for soft coat low-e glass types, and a robot that seals each unit. The lites of glass are joined by a machine-bent spacer that is filled with desiccant to absorb moisture inside the unit. Spacer ends are connected by a single metal splice. Each unit is sealed twice. ITI Glass uses an organic polysulfide as the primary seal to anchor the spacer to each lite of glass. A secondary seal of polyisobutylene (PIB) fills the area along the unit's perimeter.

At ITI Glass, insulating glass units (IGUs) are processed by a vertical BYSTRONIC automated line that can produce oversized units. The automated line includes a dedicated washer that has superior handling for soft coat low-e glass types, and a robot that seals each unit. The lites of glass are joined by a machine-bent spacer that is filled with desiccant to absorb moisture inside the unit. Spacer ends are connected by a single metal splice. Each unit is sealed twice. ITI Glass uses an organic polysulfide as the primary seal to anchor the spacer to each lite of glass. A secondary seal of polyisobutylene (PIB) fills the area along the unit's perimeter.

ITI Glass uses spacers with clear, black and bronze finishes, and offers a warm-edge spacer for improved insulating performance. Optional silicone sealing is available for long-lasting durability in structural glazing applications.

Standards and Testing

ITI Glass' internal standards for manufacturing insulating glass units meet or exceed ASTM C1036-06, ASTM C1048-04 and ASTM C1376-03.

Associated Laboratories Inc. (ALI), one of the largest third-party testing organizations in the United States, certifies IGUs from ITI Glass. ALI conducts annual in-plant audits and receives unit samples that are tested for compliance according to ASTM E2190-08 Standard Specification. Additionally, as a member of PPG Industries' Certified Fabricator Program (PPG CFP), ITI Glass submits to annual audits by PPG to ensure quality production of all products. ITI Glass has maintained continuous certification with ALI for more than 20 years and has passed all CFP audits since its acceptance into the program in 2006.